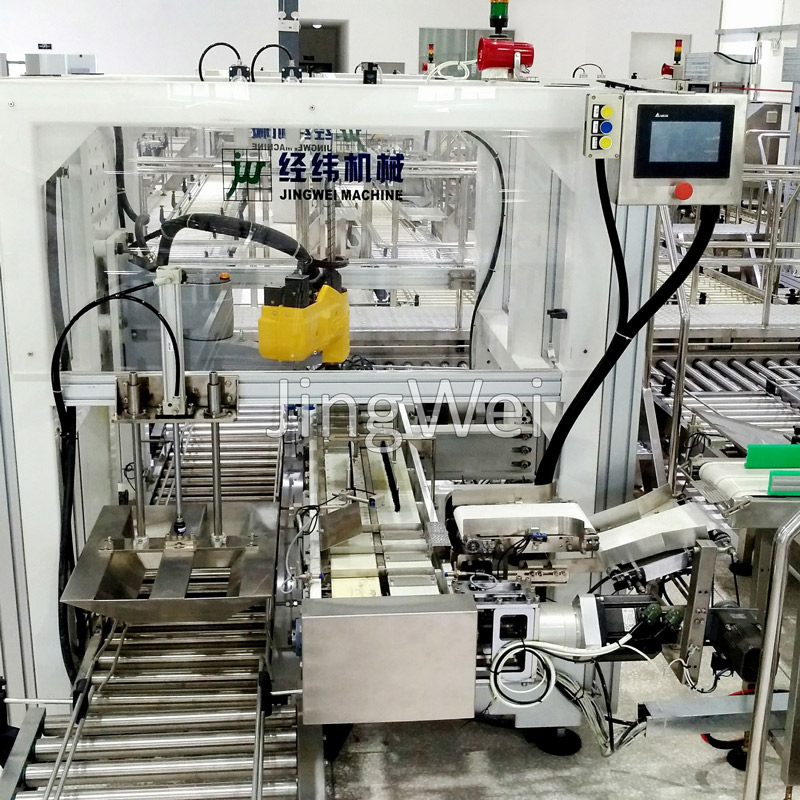

Robot Packing

Here are some general tasks that a robot packing machine can perform:

Pick and place: The robot arm can pick up products from a conveyor or production line and place them into packaging containers such as boxes, cartons, or trays.

Sorting: The robot can sort products according to their size, weight, or other specifications, and place them into the appropriate packaging.

Filling: The robot can accurately measure and dispense a precise amount of product into the packaging container.

Sealing: The robot can apply adhesive, tape, or heat to seal the packaging container to prevent the product from spilling or leaking.

Labeling: The robot can apply labels or print codes onto the packaging containers to provide important information such as product details, expiry dates, or batch numbers.

Palletizing: The robot can stack finished packaging containers onto pallets according to specific patterns and configurations, ready for shipment or storage.

Quality inspection: The robot can also inspect the packaging containers for defects such as cracks, dents, or missing components to ensure quality control.

Overall, the robot packing machine can perform a wide range of tasks to automate the packaging process, increase efficiency, reduce labor costs, and improve the accuracy and consistency of the packaged products.

Features

1. It is PLC and motion control, servo drive, HMI operation, accurate postioning and speed adjustable.

2. To achieve the automation of the whole packing process, improve the production efficiency, save the labor and reduce the production cost.

3. Less area occupancy, reliable performance, simply operation. It is widely used in beverage, food, chemical industry, medicine, auto parts and other industries.

4. Customized development and meeting the customer needs innovation.