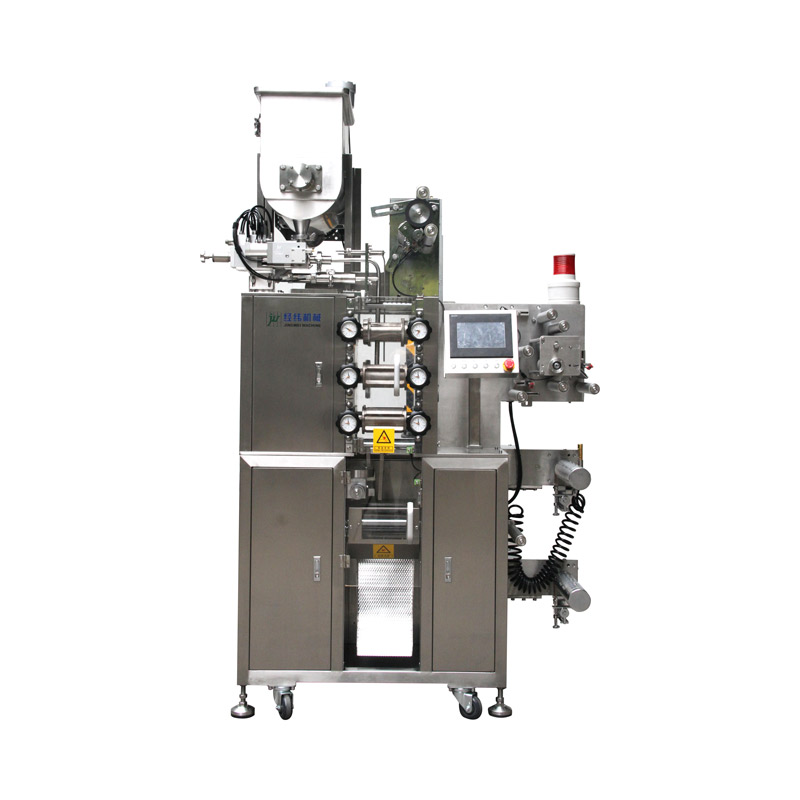

Automatic Sauce Filling And Packing Machine-JW-JG350AVHR

| Product: Automatic Sauce Filling And Packing Machine |

||

| Model): JW-JG350AVHR | ||

|

Spec |

Packing Speed | 70~200 bags/min (Depending on the bag and filling material) |

| Filling capacity | ≤100ml (Depends on the material and pump spec) | |

| Pouch length | 50~150mm(Can be customized ) | |

| Pouch width | 50~100mm | |

| Sealing type | three or four sides sealing | |

| Sealing steps | Three sides sealing | |

| Film width | 100~200mm | |

| Max.rolling diameter of film | 350mm | |

|

Dia of film inner Rolling |

Ф75mm | |

| Power | 6kw, three-phase five line, AC380V, 50HZ | |

| Compressed air | 0.4-0.6Mpa, 320NL/Min | |

| Machine dimensions | (L)1464mm x(W)1178mm x(H)2075mm | |

| Machine weight | 450kg | |

| Remarks: It can be customize for special requirements. | ||

| Packing Application Various viscous materials; such as hot pot materials,tomato sauce, various seasoning sauces, shampoo, laundry detergent, herbal ointment, sauce-like pesticides, etc. |

||

| Bag Material: Suitable for most complex film packing film in home and abroad, such as PET/AL/PE, PET/PE, NY/AL/PE, NY/PE and so on. |

||

Features

1. Operating system: Adopt flying shear synchronization technology, servo motor direct-drive control, stable operation, simple operation, speed can reach 150-250 packets/minute.

2. Filing: LRV pump, stroke pump or Pneumatic pump filling for optional choice, depend on the filling material.

3. Machine material: SUS304.

4. Realizing the automatic switching to different product packing by setting the parameters.

5. Zig-zag cutting &Flat cutting in strip bags.

6. Cold sealing can be matched with: Chessboard pattern and line pattern.

7. It can be equipped with a coding machine and steel presser to realize real-time coding for optional.

8. Liquid feeding system can be selected to realize the functions of separate and mixed packaging of sauce and liquid.

9. It is equipped with double supply film of inflatable shaft to realize automatic film change and improve the equipment productivity.