Current Situation of Packaging Machinery in the Domestic Daily Chemical Industry

Current Situation of Packaging Machinery in the Domestic Daily Chemical Industry

In recent years, the domestic daily chemical industry has experienced rapid development, with a significant increase in product variety, which has raised higher requirements for packaging machinery technology and packaging types. Currently, most manufacturers of large liquid detergent products use advanced equipment from abroad, which leads in terms of both production speed and product quality. With the rapid development of domestic daily chemical packaging equipment and the continuous manifestation of production cost advantages, advanced domestic daily chemical packaging equipment will play a greater role in enterprises.

Demand for Packaging Machinery in the Daily Chemical Industry

As people's living standards continue to improve, the demand for quality of life is also increasing. Consumers' demand for personal care products and detergents is constantly growing. Nowadays, many consumers prefer small-sized toiletries that are convenient to carry and use. This makes it essential for production companies in the detergent and personal care product sectors to focus on the accuracy of product dosage. Since these products have small dosages, inaccurate measurement can result in significant deviations. Additionally, some products have high value, and precise measurement can save a considerable amount of production costs for companies. The market demand determines that in the coming years, packaging machinery with precise measurement will be favored by enterprises. The industry's development trend will lead to an increasing demand from daily chemical companies for high-speed and highly automated equipment.

Advantages of Our Company in Small Bag Flexible Packaging for Personal Care and Cosmetics:

Our company, Jingwei, has been dedicated to the research and production of small bag flexible packaging machines since 1996. Up to now, our equipment has been selling well in both domestic and overseas markets, with tens of thousands of units sold. The equipment has evolved from originally packaging machines with a single specification to advanced devices capable of packaging different capacities and specifications. It has also transitioned from packaging bags in a single column to packaging bags in multiple columns, greatly improving packaging efficiency. In comparison with similar foreign equipment, our machines demonstrate a higher cost advantage. The equipment's packaging range mainly includes small bags of shampoo, creams, essential oils, detergents, and laundry detergent. The packaging accuracy fully meets customer requirements, and the customers who currently use our equipment are leaders in the daily chemical industry.

Meanwhile, our company has a highly intelligent and high-quality team of technical personnel and employees. Our packaging equipment has won several provincial and municipal scientific and technological progress awards and obtained multiple Chinese patents. We can meet the customized requirements of different customers and strive for excellence in terms of quality. Our after-sales service personnel are also spread across the country, capable of promptly arriving at customer sites to solve problems and providing customer satisfaction as the standard in terms of subsequent equipment services.

Packaging bag sample:

Product Examples:

Multi-Lane Small Bag Liquid/Paste Packaging Machine

Six-lane packaging machine

Three-lane packaging machine

Technical Parameters:

Packaging Capacity: 40-150 bags/minute

Filling Volume: 2-50ml Bag Length: 30-150mm

Bag Width: Four-side sealing: 30mm-90mm

Number of Sealing Segments: Three

Packaging Film Width: Up to 500mm

Maximum Film Roll Diameter: φ500mm

Film Core Diameter: φ75mm

Power: 4.5KW, three-phase 380V (±5%), 50Hz

Depth: 1150mm; Width: 1700mm; Total Height: 2400mm (maximum)

Machine Weight: 800kg

★Special customization is required for specifications beyond the above range.

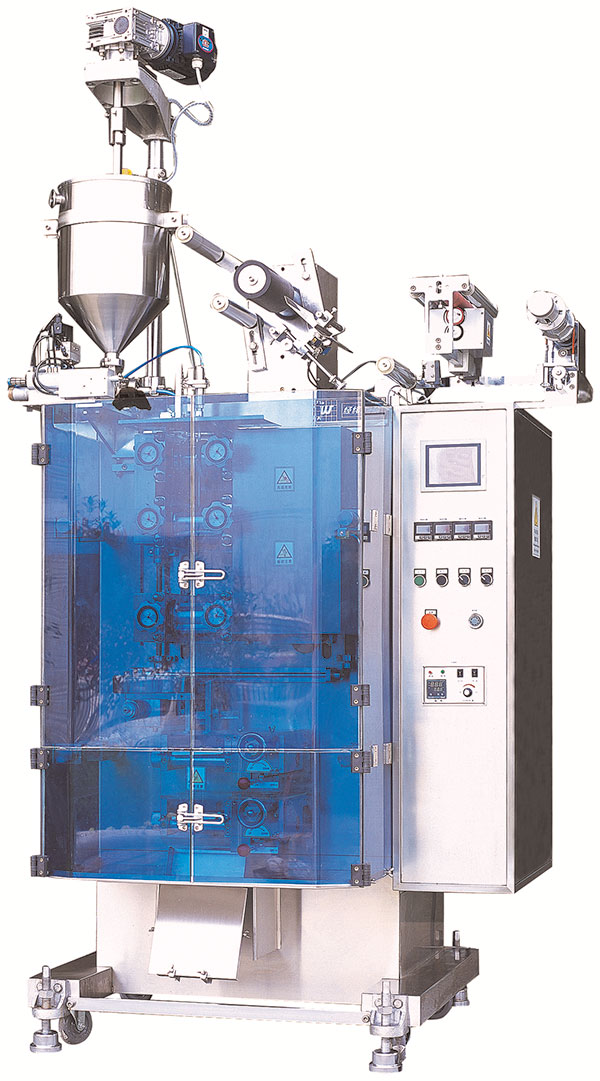

Single-Lane Small Bag Liquid and Paste Packaging Machine:

Product Model: JW-J/YG350AIII

Product Features: This machine uses a Chinese touch screen LCD display for parameter settings.

Main Parameters: Packaging Capacity: 60-200 bags/minute

Filling Volume: ≤80ml

Bag Length: 40-200mm

Bag Width: Three-side sealing: 40mm-90mm

Number of Sealing Segments: Three

Packaging Film Width: 80-180mm

Maximum Film Roll Diameter: φ400mm

Film Core Diameter: φ75mm

Power: 4.5KW, three-phase 380V (±5%), 50Hz

Depth: 1000mm; Width: 1550/1500mm; Total Height: 1800/2760mm (maximum)

Machine Weight: 550kg

★Special customization is required for specifications beyond the above range.

With the goal of improving enterprise automation, enhancing the work of operators, ensuring product quality stability, and saving labor costs, our company meticulously designs, manufactures, and assembles each equipment. We aspire for Chengdu Jingwei Machinery to become your most trustworthy and reliable partner!

Post time: Jul-14-2023